When building custom LEGO MOC cars, one of the most exciting aspects is designing a functional and realistic engine. A detailed engine not only adds authenticity to your model but also provides a sense of mechanical complexity that enhances the overall build. For MOC car enthusiasts, mastering the art of engine design can be a rewarding challenge that takes your LEGO creations to the next level.

In this blog post, we’ll explore how to design functional and realistic engines for custom LEGO MOC cars. Whether you’re a beginner looking to add a simple engine or an experienced builder aiming for intricate mechanical details, these tips will guide you through the process.

1. Understanding the Basics of LEGO Car Engines

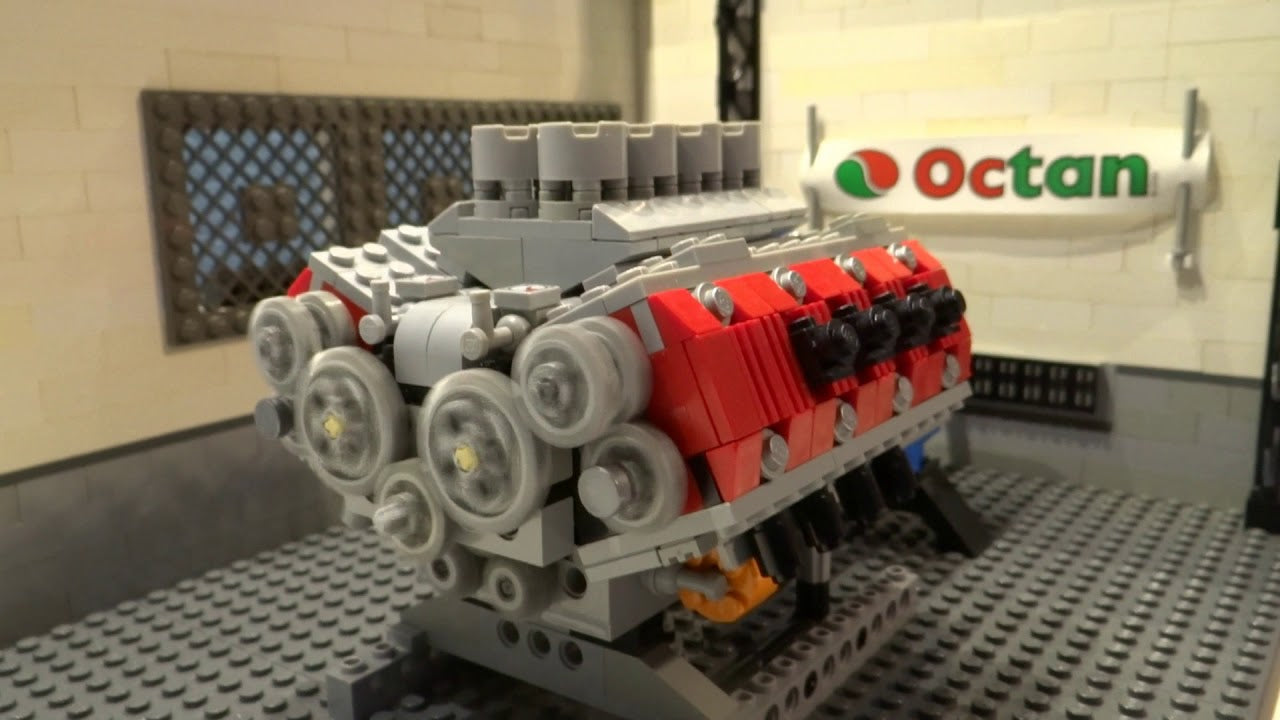

Before diving into the design, it’s essential to understand the basic components of a LEGO car engine. Most MOC car engines are inspired by real-world internal combustion engines, which consist of parts like pistons, crankshafts, and camshafts. Translating these elements into LEGO form involves using gears, axles, and Technic pieces to create a working model.

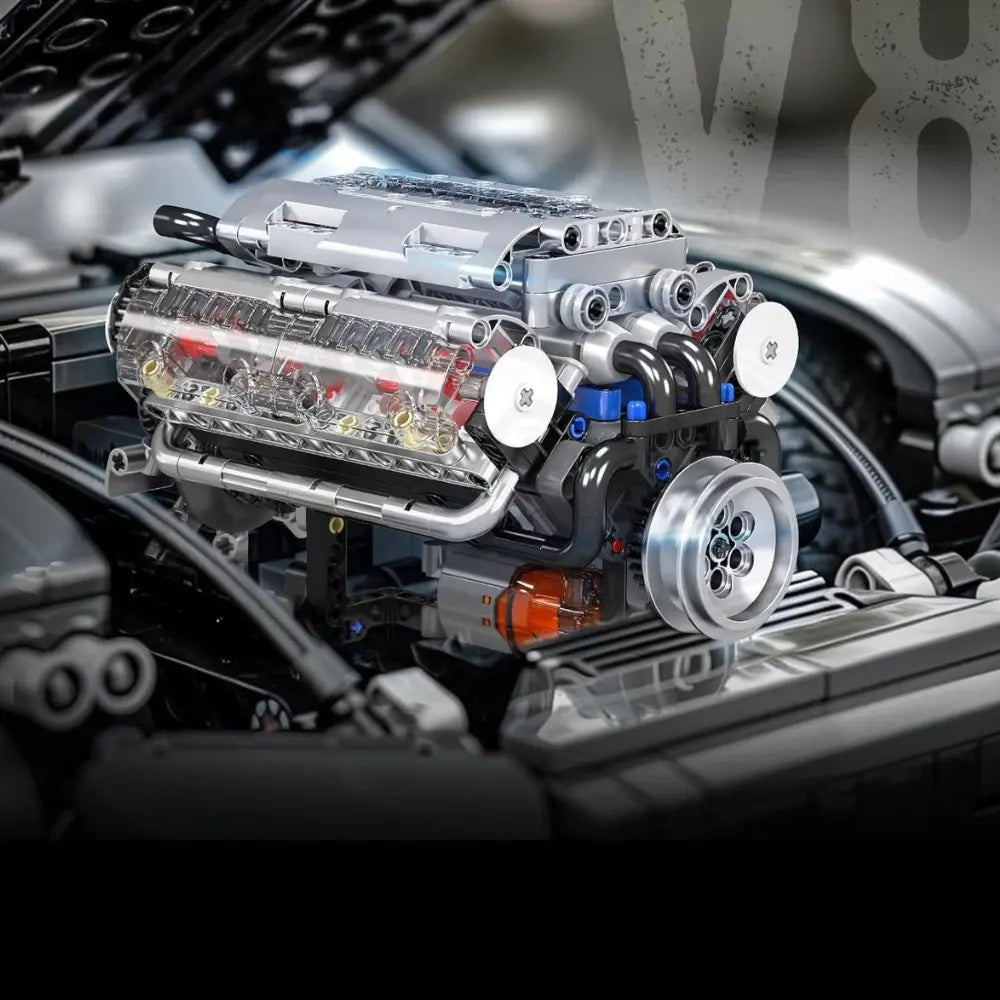

For example, a V8 engine, commonly found in high-performance cars, can be mimicked using LEGO Technic pistons and axles that move in sync as the car’s wheels turn. If you’re new to engine design, starting with simpler engines such as inline-4 or V6 models can be a good way to learn the basics.

If you’re looking for inspiration, check out our British Defender, which features a highly detailed engine block designed with these principles in mind.

2. Choosing the Right Parts for Your MOC Engine

Selecting the right parts is crucial for creating a functional engine that not only looks good but also works. LEGO Technic parts are the go-to choice for most MOC car builders, as they offer the mechanical complexity needed to replicate real-world engine functions. Pieces like gears, axles, and pistons can be used to simulate moving engine components.

Here’s a breakdown of some essential parts for building a LEGO MOC car engine:

- Pistons: LEGO Technic pistons are available in various sizes and can be connected to crankshafts to mimic the up-and-down motion of real engine pistons.

- Crankshafts: Use Technic axles and connectors to build crankshafts that drive the pistons’ movement.

- Gears: Gears are critical for transferring rotational movement from the wheels to the engine. Different gear ratios can affect the movement of the engine, so experiment with sizes for optimal performance.

If you’re working on a smaller MOC car, it might be challenging to fit all these elements inside the engine bay. In such cases, consider scaling down the engine or incorporating just the visible parts, like the engine block and intake manifold, to maintain the aesthetic.

3. Making the Engine Functional

Designing a functional LEGO MOC car engine means more than just having moving parts. For many builders, the ultimate goal is to create an engine that interacts with other components of the car, such as the wheels or drivetrain. To achieve this, you’ll need to connect the engine to the car’s transmission and axle system, allowing the pistons to move when the wheels turn.

One popular way to do this is by using a gear system that links the wheels to the crankshaft. When the car moves, the gears rotate the crankshaft, causing the pistons to pump. This type of functional engine is not only satisfying to build but also adds a new layer of interactivity to your MOC car.

For more advanced builds, consider incorporating LEGO motors to power the engine. This can simulate the experience of an electric vehicle or a high-powered sports car, with the engine parts moving autonomously.

4. Adding Realistic Details

A custom LEGO MOC engine isn’t just about functionality—it’s also about capturing the visual essence of real engines. Adding realistic details can turn a basic engine into a show-stopping centerpiece of your MOC car.

Here are some ideas for adding realism to your engine:

- Hoses and Pipes: Use flexible LEGO tubing to simulate hoses, pipes, and fuel lines that run through the engine bay.

- Air Intakes and Turbochargers: If you’re building a supercar or muscle car, consider adding a turbocharger or supercharger. You can create this effect using round LEGO bricks and Technic connectors.

- Color Coordination: Real-world engines often feature color-coded parts (such as red valve covers or chrome intakes). Replicating this in LEGO form adds visual interest and breaks up the monotony of a single-color engine block.

5. Testing and Refining Your Design

Once you’ve built your engine, it’s important to test its functionality. Rotate the wheels and observe how the engine parts move. If the pistons aren’t moving smoothly or the gears are slipping, try adjusting the alignment of the crankshaft or swapping out gears for ones with a different ratio.

Testing also gives you the opportunity to refine your design. You might discover that certain details, like a complex turbocharger, don’t quite fit into the engine bay. Don’t be afraid to modify your design until it achieves both functionality and aesthetics.

Conclusion: Build Your Dream LEGO MOC Car Engine

Designing a custom LEGO MOC car engine is a rewarding process that combines creativity, technical skill, and attention to detail. By selecting the right parts, incorporating functional components, and adding realistic details, you can create an engine that not only looks impressive but also enhances the overall experience of your build.

Ready to start building? Check out our range of custom MOC cars for inspiration, and stay tuned for more tips on improving your LEGO car-building skills!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.